Tell : 0086 135 1058 5626 E-mail : info@nasn.cn

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-12-12 Origin: Site

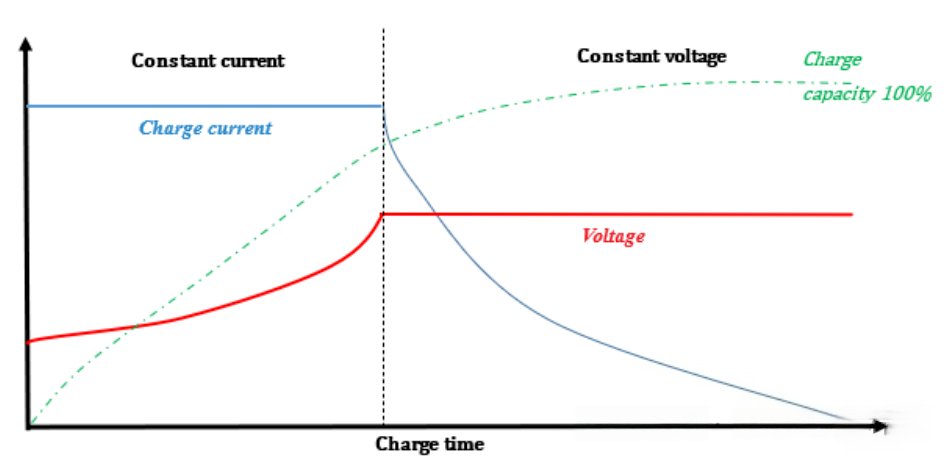

Understanding the constant current (CC) and constant voltage (CV) stages is key to understanding how lithium batteries can be charged safely, quickly, and healthily.

We can use a perfect metaphor of pouring water into a cup to fully understand it. Imagine charging your electric car battery, like pouring water from a kettle into a very delicate and expensive narrow mouthed glass.

·Water kettle=charging station (power source)

·Water flow=charging current

·The water level in the cup=battery voltage

·The maximum capacity of the cup is equal to the voltage when the battery is fully charged (such as 4.2V battery cell)

Your goal is to pour water into the cup quickly and efficiently, but never spill a drop (overfilling) or damage the cup due to excessive water flow.

Phase 1: Constant Current Charging - "Full Sprint for Water Filling"

When the cup is still empty and the water level is low. In order to fill up quickly, you tilt the kettle to a fixed and maximum safe angle, allowing a strong and stable stream of water (constant current) to continuously flow into the cup. This is just like when the state of charge (SOC) of a battery is low, its voltage is also low. The charging station will apply a 'constant high current' (for example, the maximum current negotiated between the vehicle and the charging station, such as 250A). It is obvious that:

1) Rapid increase in water level (voltage): As the current continues to be injected, the battery voltage steadily and rapidly increases;

2) This is the "main stage" of charging: about 80% of the battery's charge is quickly charged during this stage, so it is the key stage to pursue charging speed.

At this stage, the charging station is the 'current source', whose task is to maintain a constant current. The vehicle's battery management system (BMS) is like a supervisor, monitoring the voltage in real time to see when it is about to reach its peak.

Phase 2: Constant Voltage Charging - "Carefully Fill"

When the water level (voltage) rises very close to the cup mouth (full charge voltage), if you still maintain the high water flow just now, inertia will cause water to overflow the cup (overcharge), which is absolutely prohibited! At this point, you must immediately adjust the action: keep the height of the kettle mouth constant (i.e. keep the "water pressure" of the cup mouth constant), and then gradually and slowly reduce the tilt angle of the kettle (reduce the current).

This is like when the battery voltage rises to the preset charging termination voltage (e.g. 4.2V/cell), the charging phase switches. Switch the charging station to the "constant voltage source" mode and maintain this voltage absolutely unchanged. At this point, it will occur:

1) The voltage is' nailed 'to its peak value: it no longer rises, preventing overvoltage damage.

2) The current begins to naturally decay: As the chemical potential inside the battery becomes closer to the externally applied voltage, the "pushing force" that drives the charge into the battery becomes smaller and smaller. Therefore, the charging current will gradually decrease like a natural downward curve, and the BMS will continue to monitor the current.

3) This is the 'leakage filling stage' of charging: the battery is charged from 80% to 100%. The speed is getting slower and slower, like filling the last few corners. When the current decreases to a very small preset value (e.g. 0.05C, which is 5% of the maximum current), the BMS considers the battery to be "substantially fully charged" and sends a command to completely stop charging. Just like when you see the water flow turning into small droplets, you turn off the faucet.

Why do we need these two stages charging?

Constant current (CC), speed, quickly irrigate with maximum safe water flow, shorten charging time, and achieve rapid energy replenishment under safety conditions. If an empty battery is charged with maximum voltage from the beginning, it will generate a huge current, which may instantly damage the battery.

Constant voltage (CV), safe and healthy, carefully filled. It can prevent overcharging, complete the final charging with a small current, reduce the chemical stress inside the battery, extend the battery cycle life, and ultimately enable each cell of the battery to reach a true full charge state.

The two-stage charging of constant current (CC) and constant voltage (CV) is an engineering compromise and control art that achieves optimal, safe, and efficient energy transfer between the nonlinear electrochemical characteristics of batteries and linear controllable power sources. The constant current (CC) stage utilizes the small polarization of the battery in the low/medium SOC range to maximize power and solve the pain point of "slow charging"; The constant voltage (CV) stage respects the physical reality of the rapid increase in polarization of the battery in the high SOC range, strictly controls the voltage boundary, and solves the core problems of "unsafe overcharging" and "loss of life due to overcharging".